OEM/ODM

Good design comes from thinking

Our products are now sold worldwide, spreading light and innovation across the globe.

We designed a solar motion sensor lamp -UFO, from the "nature" of the beauty Our products idea are inspired by blessing for everyone

The UFO solar lamp started its conception from a blessing, the white calla lily, as bright as the sun, represents respect, love, happiness, and blessings. We hope that people will pass on their good wishes and blessings to everyone around them.

An ODM manufacturer offers a stylish solar wall light with a human body infrared sensor, providing 360-degree UFO-style lighting

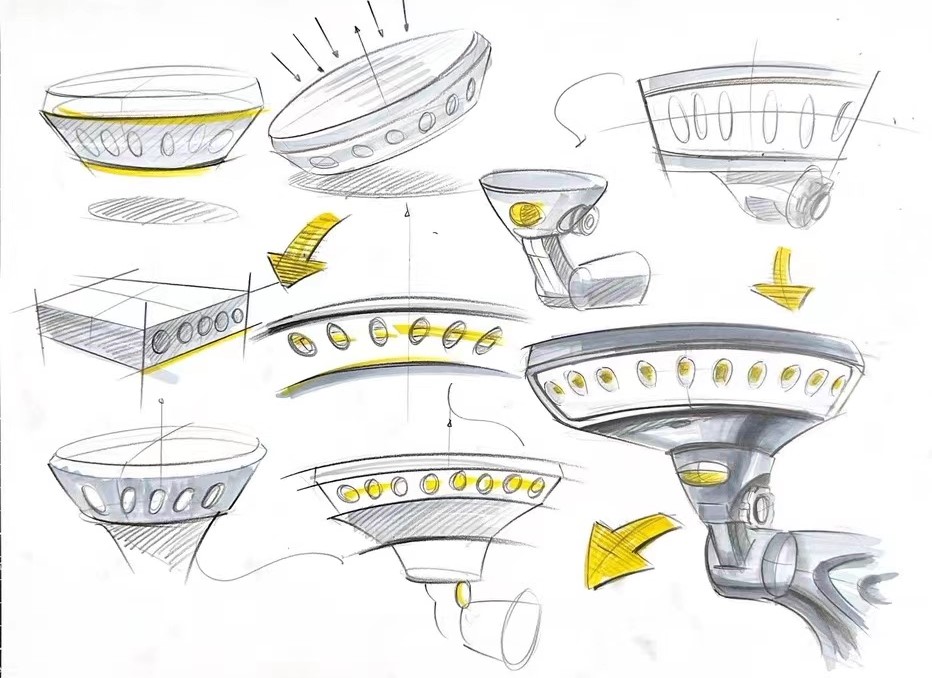

Product Design-Hand Drawn

The Designers First Step. it is original and shows great creativity and imagination.

Production

The Designers design concept and exquisite skills have turned this design into stunning and perfect artwork.

Product Shipment

Product are exported to more than 20 countries/regions. Customers customize their own packaging boxes.

Comprehensive Solutions, Complete Excellence | Top ODM Manufacturer Services

We have a complete industrial line

We are a leading ODM manufacturer and can provide the best prototypes, rapid prototyping, and small-batch production services to meet customer needs. We have a first-class team of engineers and technicians, as well as related production equipment, to quickly transform your ideas into real products with high cost performance

3D printing

Electronic circuit design

ID Design

Product structure design

Mould Making

Finished Product

Unmatched Quality & Innovative Lighting Solutions | Trusted ODM Manufacturer

Why Choose Watt Valley Solar?

Empower Your Progress with Hangchi Solar: Elevating Illumination Standards, Assured.

Empower Your Progress with Watt Valley Solar: Elevating Illumination Standards, Assured. In the world of solar lighting, selecting the right provider is paramount to ensure not only efficient illumination but also long-term reliability. Watt Valley Solar stands as a premier choice for numerous reasons:

- Rich experience: Since Watt Valley establishment in 2015, we have been focusing on the research and development and manufacturing of solar lighting products for nearly ten years.

- High Production Capacity: With four production lines, we can meet large-scale demands efficiently.

- Our customers are all over the world, with more than 100 distributors, wholesalers, importers and retailers cooperating with us.

- ODM/OEM Manufacturer: The unique design concept of designers and the professional R&D technology of engineers are the key to our products' competitive advantage and quality assurance.

- Competitive Pricing: Cost-effective options without compromising quality.

- Exceptional Support: Professional sales will answer all your questions, strong production capacity will ensure timely delivery, and considerate after-sales team will relieve your worries. Prompt and transparent communication is our commitment.

- We have professional designers and engineers who can quickly provide product appearance drawings, 3D pictures, and structural design drawings according to customer needs. This saves you a lot of time, energy, and cost. At the same time, we have a complete supply chain system. We make PCB boards, solar panels, and assemble products by ourselves. Any production link can be well controlled, and product quality and delivery time are guaranteed.

Custom Design, Expert Manufacturing | Your Trusted ODM Partner for Quality Solutions

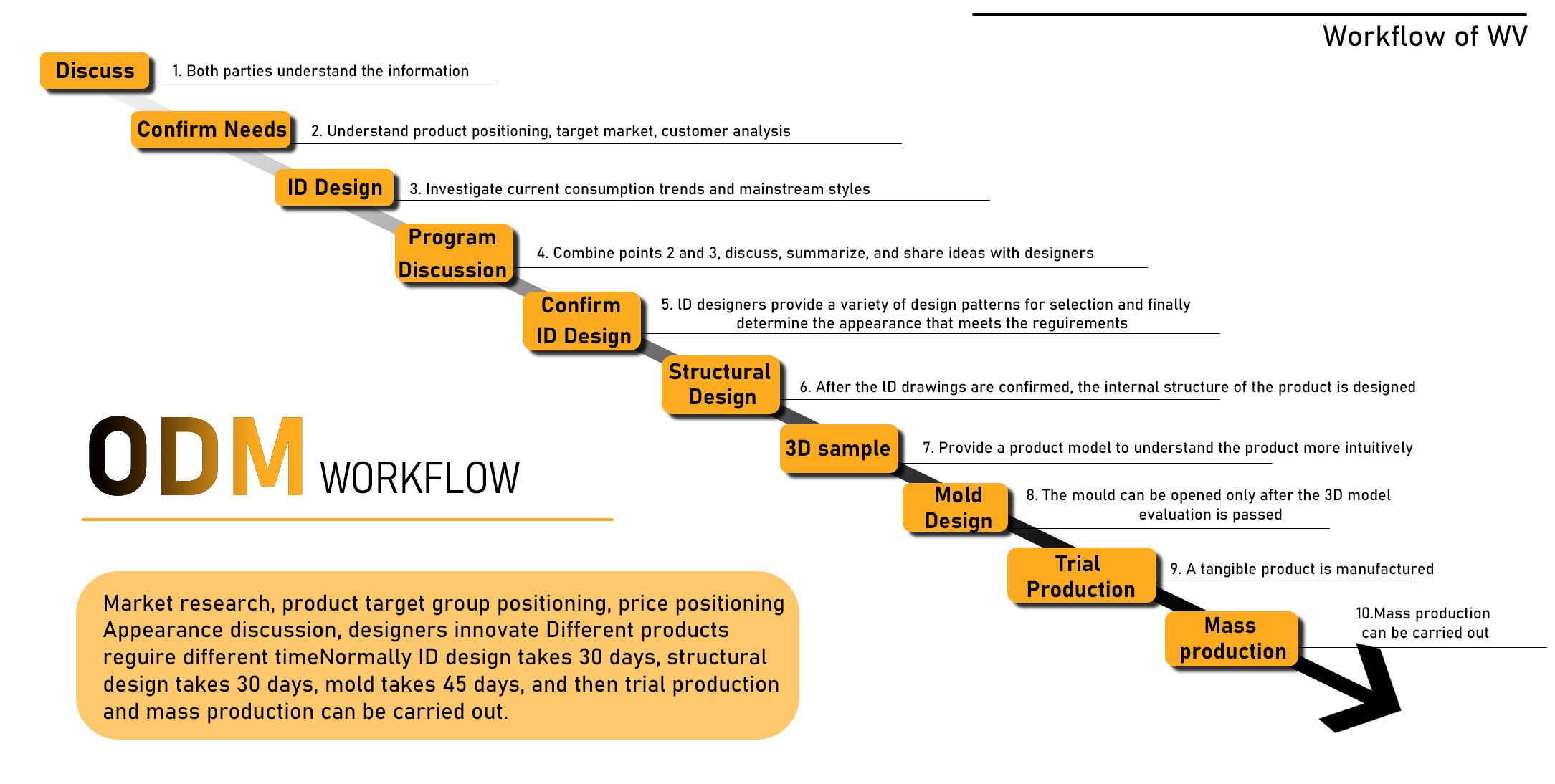

What is the process of ODM?

Your Brand, Our Expertise

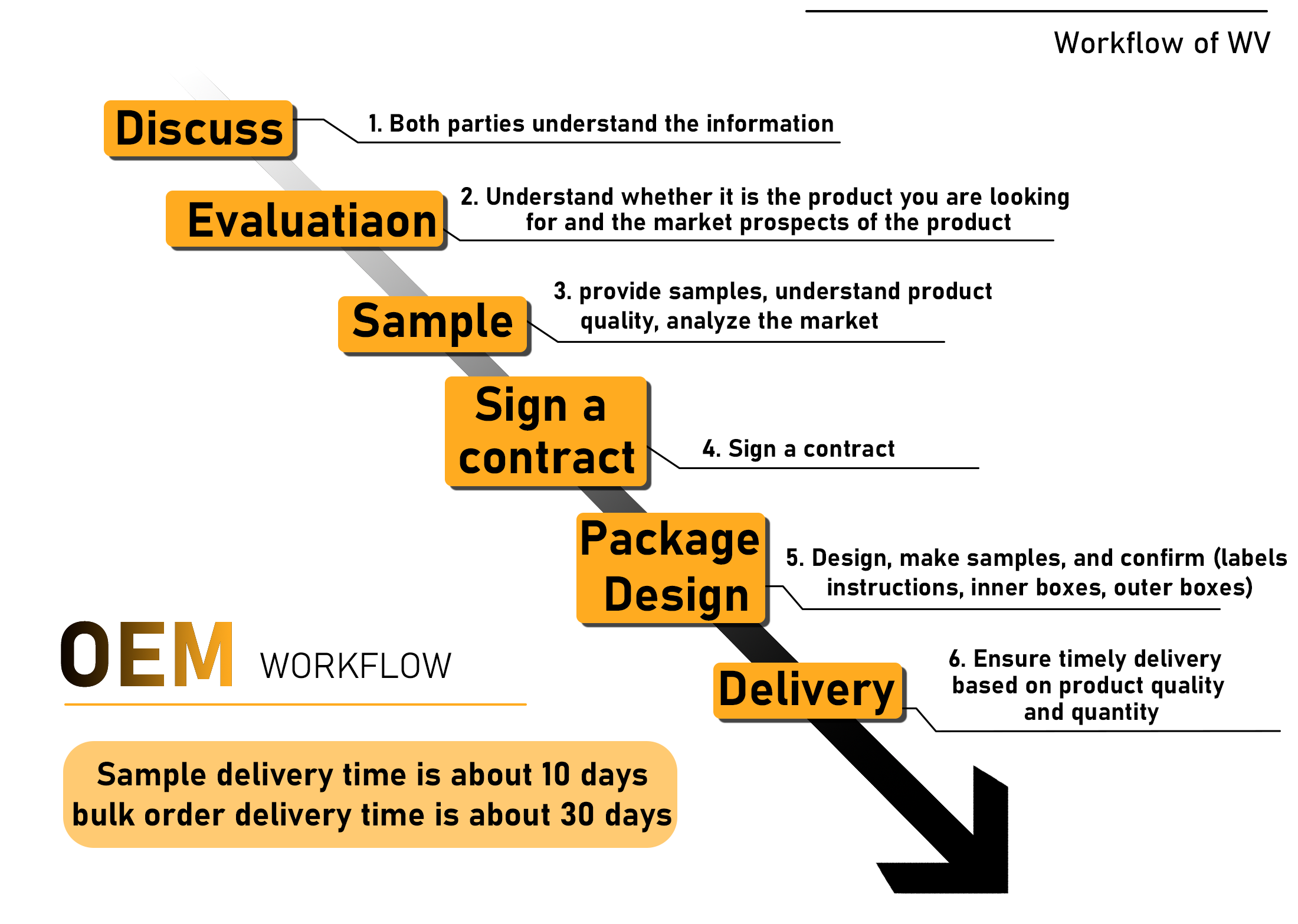

What is the process of OEM?

Injection molding machine

The shell of a plastic product is formed by processing with an injection molding machine. There are many types of rubber particles used for injection molding, usually ABS plastic, polystyrene (PC), polypropylene (PP), etc. The requirements for the properties of plastics vary depending on the usage environment and region. For example, UV plastics can maintain good performance in outdoor environments and extend their service life. 2. Compliant with UL V-0 flame retardant standard. 3. Compliance with ROHS requirements requires strict control in this process, and a sound industrial system is the guarantee of product quality.

Mold is the mother of industry, is the source of products, to do a product, you have to start from the mold. Our partners have perfect production mold equipment, can achieve low cost, high efficiency and quality assurance mold.